Some materials about chip-making developments, particularly about the birth of the Perkin Elmer Projection Scanning Aligner…

From 1999, this 8 page article (PDF) as linked from The Chip History Center here.

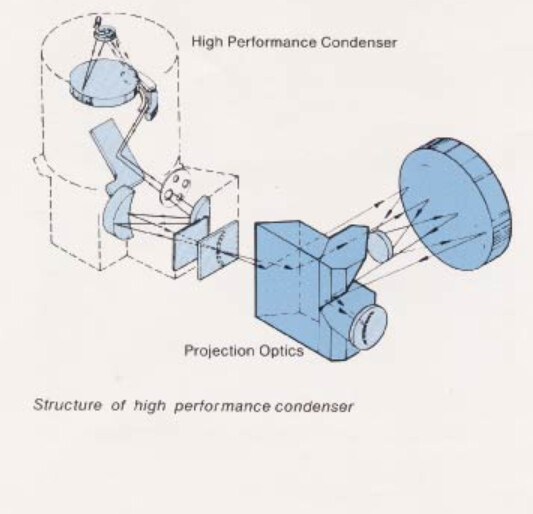

When its first projection device needed 16 lenses, Perkin-Elmer decided to try a new approach

According to the article, even a 2 inch wafer needs the equivalent of 300 megapixel resolution.

Early marketing materials emphasized the enormous improvement in mask life. “Contact printing was godawful,” Bossung says. “The emulsion [on the masks] would lift off. . . . After ten uses, the masks were useless.” Buckley agrees: “Places like TI were buying masks, literally by the truckload, using them six to ten times, then putting them in the landfill.” By contrast, the Micralign offered mask lifetimes of at least 100,000 exposures.

Ultimately, the Micralign scanner made the personal computer possible by allowing the necessary microprocessors to be manufactured cheaply enough for a reasonably priced unit. In June 1978 Intel introduced the 8086 chip. A year later came its sister chip, the 8088, which was used in the first IBM PC. These chips were about one-fifth of an inch square and contained some 29,000 transistors each. With contact printing, only 20 percent of these chips were salable. With the Micralign, the yield shot up to 60 percent.

Also this article and links within:

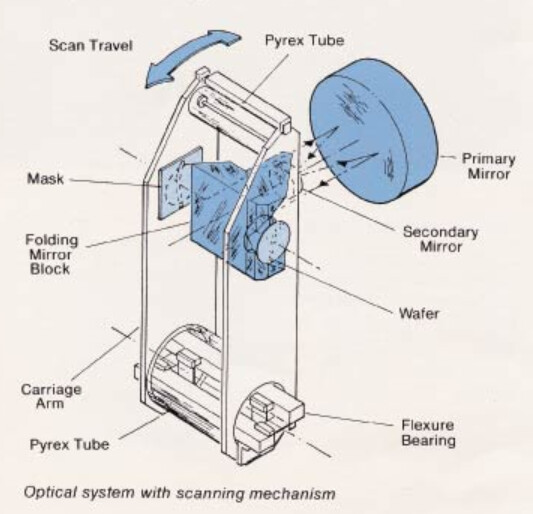

Perkin Elmer - Micralign Projection Mask Alignment System

Here we have the aligner that literally made the modern IC industry. Prior to its introduction contact and proximity aligners were the only available units. Yield was notoriously low, at 10 or 20%, often nearer zero. Intel reputedly worked with Perkin-Elmer to secretly arrive at its design. Word began to leak out that Intel had this marvelous new aligner which yielded in the 70% range.

And a half hour talk at “The Projection Aligner: Its development at Perkin Elmer in the 1970’s”

Also Perkin-Elmer’s brochure on the web here has a nice overview of the technical challenge and motivation.

Nearby, an intermediate technology, the proximity aligner:

Proximity aligners were a bridge tool between the original contact aligners and projection aligners. Yield from contact aligners was extremely low, mainly because the mask was just a stencil laying over the photoresist. It would smear and scratch the resist when in contact and then pull off some of the resist upon being removed. Proximity aligners would position the mask about 5 microns above the resist—i.e. in proximity. This was quite a feat in its day, requiring alignment through six degrees of freedom while holding mask flatness even tighter.