A nice collection of articles and images (most of them from TekTalk) around CRT manufacturing at Tektronix:

https://vintagetek.org/crt-manufacturing/

E.g., as of May 1957, we learn about the process as follows:

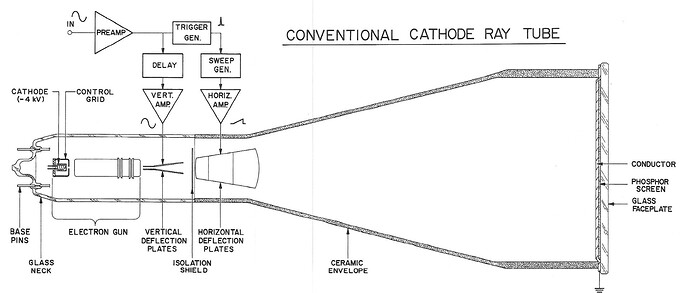

Gun making is done in four steps; namely, gun assembly, gun wiring, gun sealing, and final inspection and pinning.

The gun assembly consists of the various elements of an electron gun being mounted in a jig in a very exacting position which is held to a tolerance of .001 of an inch. Then the jig-gun is forced into molten pyrex glass rods which have been heated by an intense oxygen and propane flame. This production method insures Tek of a consistently accurate gun for its CRT.

The wiring phase of the gun production consists of two basic opera- tions. The first is spot welding ni-chrome wire which is used to connect the assembled elements to the gun. The second operation is spot welding various shields to certain elements to minimize foreign external interference. No soldering kind is used in this of any very exacting work. There is no sub-assembly in this step as each girl is responsible a for wiring a complete gun.

After wiring, the gun is ready to be sealed into a two inch special lead glass tubing. Sealing is done in a special horizontal glass-sealing lathe. A glass stem which supports the gun is inserted at this time. All glass area is annealed to remove strains in the glass.

The department is proud of its latest acquisition, a vertical sealer, which will step up production greatly. We will try to give you a special report on this when it goes into action. After the sealed gun is cooled, excess glass is cut off at a predetermined point in the gun. Filaments are checked; and the gun is ready for Final inspection.

Checking of X-plates, parallelism as to width and spacing, other miscellaneous checks, loose connections and then alignment of the gun inside the tube. The last step consists of spot welding and mounting the deflection plate leads to the gun. The precision built gun demands the accuracy that individual thoroughness alone can achieve. It does not lend itself to assembly line production.

The ever important jig and other specialized equipment were developed in the Model Shop. The CRT maintenance men are responsible for the very fine spot welders that are used.

(Image: Tektronix, TekWeek Oct 25, 1975, PDF linked in the article.)

Via HN (currently in the second chance pool): https://news.ycombinator.com/item?id=31153453